A conversation with Stefan Lehner, Head of Customer Success (CUS) at Blickfeld

Stefan Lehner has built the Customer Success Team and manages various customer projects. In this interview, he discusses the tasks of the Customer Success Team and the role it plays within Blickfeld.

When Blickfeld was founded in 2017, LiDAR sensors were bulky, maintenance-intensive and very expensive to produce. Blickfeld’s founders set out to change that: They developed a LiDAR sensor with a simplified set-up, always keeping scalability in manufacturing in mind.

This year, the Utopia Stage at Rock am Ring belonged to Blickfeld LiDAR sensors! A total of six sensors have been installed above the main stage of the popular music festival to capture test recordings for the LidarPredict project, supported by mFUND.

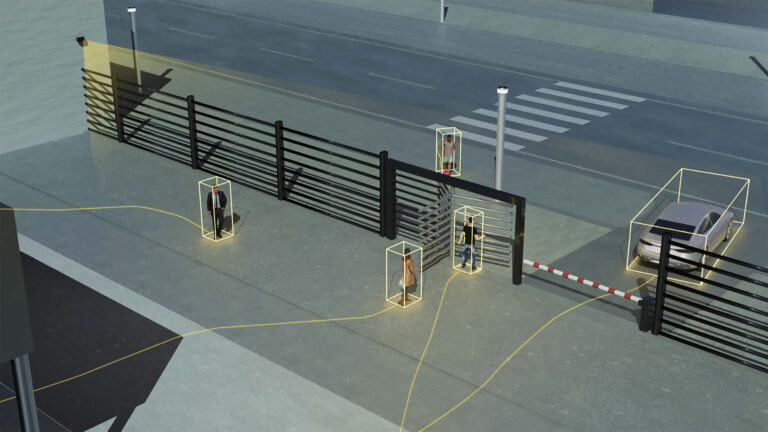

A central factor in the perimeter protection of private and public security areas is the reliable and early detection of intrusion attempts – in any weather and even in darkness. This is particularly essential in critical infrastructure to prevent sabotage, for example, against power and water supply facilities or the railway network.

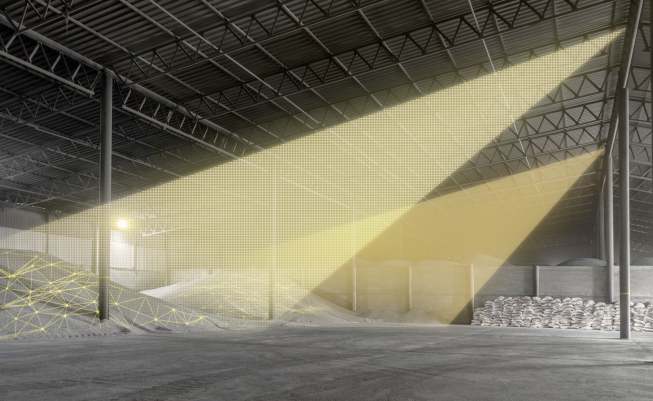

Digitalization has become a necessity for companies to stay competitive. In a recent webinar, Terje Noevig discussed how LiDAR technology can support digitalization efforts and enhance business operations by sharing customer examples.

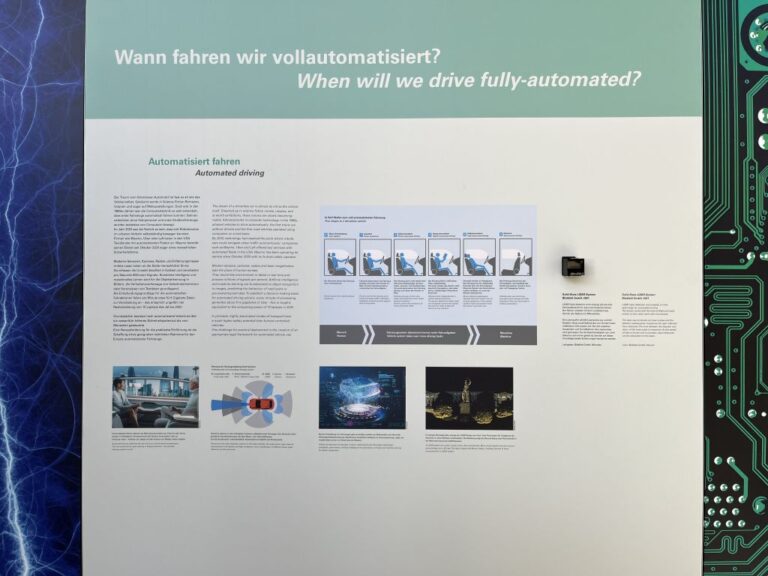

The Transportation Center (Verkehrszentrum) in Munich now features a Blickfeld LiDAR sensor within an exhibition on the Future of Mobility.

In a guest article for all-electronics.de, a widely read magazine on industrial digitization and automation, Blickfeld co-founder Florian Petit discusses the remarkable transformation that LiDAR technology has seen in the last five years. The focus is on three applications that show how LiDAR solutions deliver added value to companies in different industries:

As Chief of Marketing (CMO), Luisa Martens has been in charge of marketing and product management at Blickfeld since January 2023. In this chat, she tells us about her plans for her teams, shares one of her most valuable learnings, and her favorite tradition at Blickfeld.

Mike Yang became part of the Blickfeld management team as Head of Sales China, and in this chat, he shares his plans for the Chinese market and one of his most valuable learnings from the past years.

The terrible images of the 2010 Love Parade in Duisburg are still fresh in people’s minds. From a density of six people per square meter, the risk increases sharply that one can no longer move freely. There is then a danger that individuals will simply be swept along by the crowd and lose control of their direction of movement. Modern crowd management can help prevent this.

In Munich, the days are getting shorter, the city is decorated and even the first snow has already fallen – in short, the year 2022 is drawing to a close. As every year, we like to use this time to look back on the past 12 months and see what has happened.

The wide range of possible use cases for Blickfeld LiDAR sensors was once again reflected in the trade fair participation in the fall of 2022. Three completely different application areas were in focus from September to November. Blickfeld solutions were of great interest at leading international trade fairs for security, powder and bulk solids processing, and smart cities.

Environmental Services & Solutions Expo